NEW BUILDINGS

PLAN APPROVALS

Plan approval is the cornerstone of any new building process, directly impacting the design, efficiency, safety, reliability, and profitability of your vessel. Any overlooked anomalies can be costly and damage your company’s earning capacity and reputation. Achieving impeccable plan approval requires specialist knowledge, experience, and a deep understanding of complex systems and consequences of potential failures.

Although all designs are Class approved, it is not uncommon to find gaps between the plans and actual implementation often noticed due to lack of experience, oversight or the Rules lagging cutting-edge technologies. Additionally, shipyards, restricted by cost, deadlines, or shortage of experienced staff, may not always deliver the best designs, leading to unforeseen and costly delays and avoidable breakdowns.

At NIMRANA, our systematic approach to plan approval process is implemented by highly experienced engineers who use the best engineering practices learned through decades of specialising in the industry. Our talented engineers will ensure that every vessel is designed and constructed to the highest standards of safety, quality, and reliability for timely and trouble-free delivery and operations throughout the life of your vessels.

Choose NIMRANA for meticulous plan approval to safeguard your investment with the assurance of reliability and optimal ship performance.

CONSTRUCTION SUPERVISION

At NIMRANA, we understand that the construction of LNG vessels demands meticulous attention to detail and adherence to the highest standards. Despite the rigorous approval process by Class surveyors, large-scale projects involving thousands of components coming together in limited time can still face slips and oversights.

To ensure that your vessel is built precisely to approved drawings and specifications, our specialized site engineers are on hand to supervise every aspect of the construction process. Our team ensures flawless welding, sound coatings, and adherence to safety and quality standards. They oversee installation, commissioning, sea and gas trials, and compliance with all applicable Class, national, and international rules and industry standards.

NIMRANA’s site engineers confirm that vessel and machinery performance meets the design, specifications, and contractual agreements. Our highly qualified and experienced professionals come from diverse backgrounds, including Class societies, shipyards, and senior plan-approval engineering roles, each with decades of engineering, surveying and sailing experience.

With NIMRANA, you can be confident that every detail of your LNG vessel construction is managed with expertise and precision, safeguarding the best interests of both Owners and Charterer.

FACTORY ACCEPTANCE TESTS (FATs)

Factory Acceptance Tests (FATs) are critical to validating the functionality, quality, and compliance of machinery before it is installed on the vessel. At NIMRANA, our experienced engineers bring decades of experience in LNG ship machinery testing and validation. Their deep knowledge ensures that every aspect of the machinery is thoroughly examined and verified.

Conduct functional tests to ensure machinery performance against design specifications.

Perform stress tests to confirm machinery can withstand operational demands.

Witness non-destructive tests on parts and equipment as necessary to ensure integrity and safety.

Provide detailed analysis and recommendations for any identified issues.

Ensure transparency and traceability of all materials and test activities.

Address any client concerns or queries in real-time during the testing process.

Obtain formal client approval before machinery is shipped out to the building yard.

SEA AND GAS TRIALS

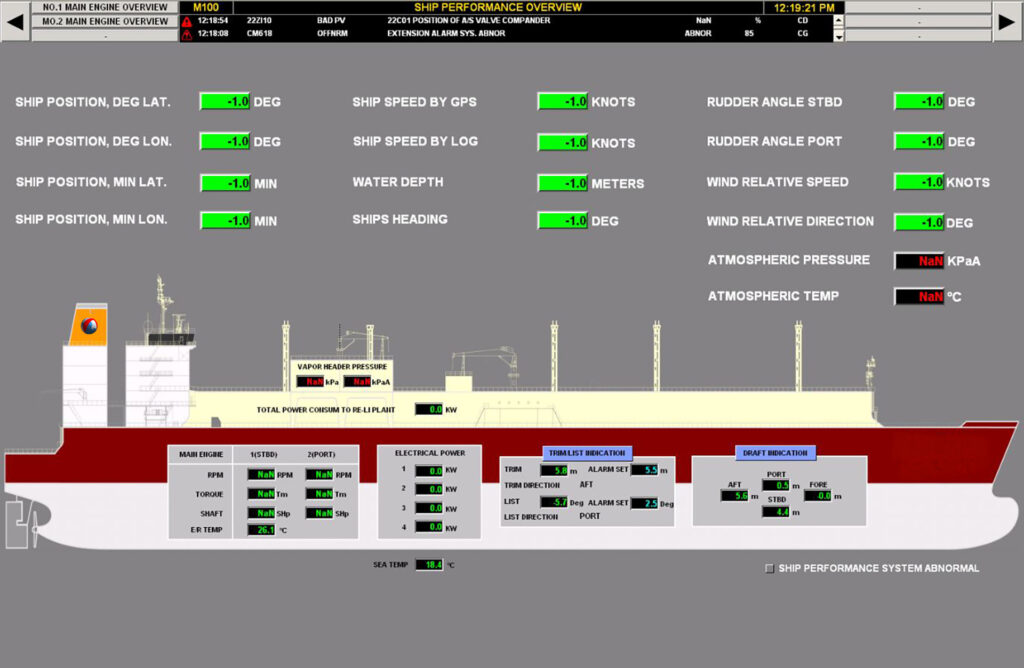

Sea trials are a critical phase in the construction and commissioning of an LNG carrier, providing an essential assessment of the vessel’s performance, safety, and operational readiness. At NIMRANA, we ensure that your LNG carrier meets the highest standards before its delivery.

Evaluation of propulsion and manoeuvrability, speed and fuel consumption optimisation.

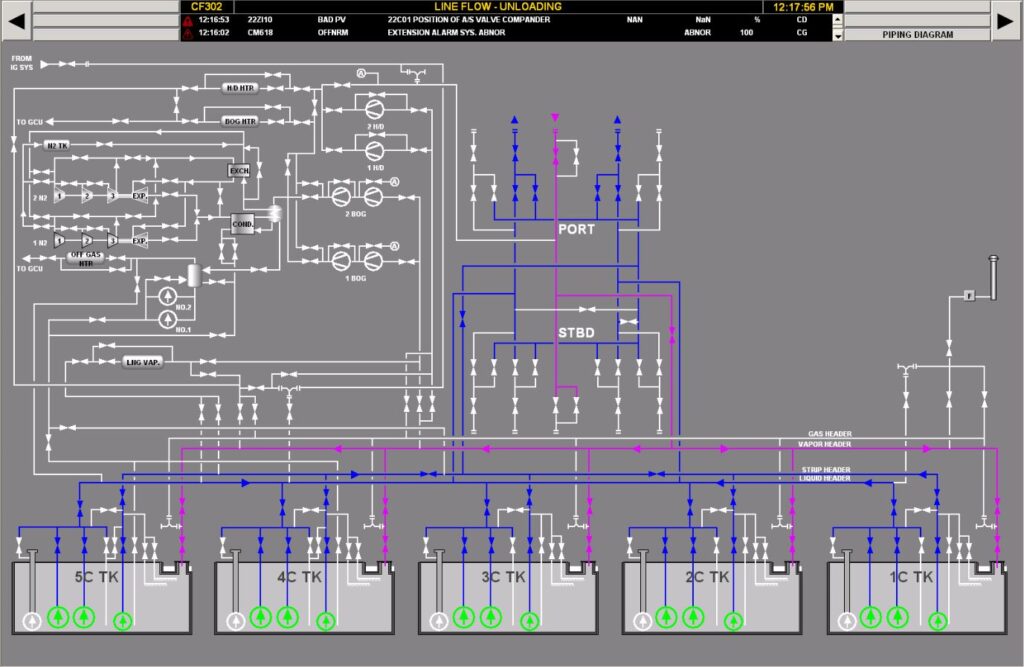

Testing of cargo handling systems, cargo operations, including LNG containment and transfer systems, and reliquefaction plant.

Assessment of navigation, communication, and safety equipment.

Verification of machinery performance under various load conditions.

Safety and Compliance Checks

Comprehensive testing of emergency systems, including fire suppression and lifeboat deployment.

Ensuring compliance with international maritime regulations and standards.

Validation of environmental controls and emissions compliance.

Detailed recording of all trial data, including speed, fuel consumption, and system performance metrics.

Analysis of trial results to identify any discrepancies or areas for improvement.

OPERATING MANUALS

Ship operating manuals are crucial for the safe operation of the ships and machinery and the overall safety of assets. Most importantly, they should be correct representation of shipboard systems and free from errors.

NIMRANA can produce professionally scripted and edited Ship Operating Manuals in English, covering the following areas of ship operations:

- Cargo Systems

- Machinery Systems

- Bridge SystemsSafety Systems

Comprehensive details of the plan with budgetary prices will be submitted for approval once the full Scope of Work is available.